You’re finally at the end of your Lola build and it’s not working right. That sucks. Have no fear; we’ll help you get it fixed. This guide is set up to help you isolate the issue.

Testing Limitations

Troubleshooting a build is tricky, particularly when it's a 500 series build. You'll need to be able to power and send signal to the unit while having access to the PCB. This can be done by using an extender jig or having a multiple space rack you can empty to gain access.

If you don't have a way to safely power and test the unit, consider sending it in for flat rate repair.

Op-amp issues

The op-amps are 50% of the mic-pre circuitry. Start by trying to rule out an op-amp issue. If R31 and R32 smoke and burn, you absolutely have a short on DOA1. If R36 and R37 smoke and burn, you have a short on DOA2. If you purchased assembled DOAs from Hairball Audio, contact us for replacement. If you built your own 990s, you likely have Q8/Q9 location and orientation issues, or CR9 and CR10 orientation. Also confirm their leads are not shorting to the Q8 and Q9 clips.

If you don't have smoking resistors but no audio, try different op-amps if you have some. Any API 2520 compatible op-amp will do. You can swap op-amps to isolate the issue to a single op-amp.

Power Supply

Power your unit and measure your supply. Relay power pins should measure -13 VDC on each pin when in the OFF position. You can measure the power pins at the leads of the 1N4004 protection diodes in front of each relay. The line-in and polarity relays are OFF by default until the pushbutton is pressed in. The DI relay is ON by default and is turned OFF by inserting an unbalanced instrument cable into the DI jack. In this default ON state, the DI relay should read -13 VDC and +13VDC at its power pins. If your DI relay is not powering properly, you may notice that your DI works fine and your XLR in does not work at all. In this case you need to examine the relay circuit and confirm all components are installed correctly and all solder joints are good.

Check your supply voltages using the chart below. Note the GND pin designation and use that as your common/black probe reference. Try measuring your op-amp supply pins with the op-amps installed and uninstalled. There should be no change. No AC signal is required.

Power Supply Test Points PDF Download

- No positive or negative voltage would indicate and issue with your rack or D1/D3.

- Op-amp supply reads properly without op-amp but is low with op-amp indicates an op-amp issue

- Op-amp supply reads bad with/without op-amps indicates an issue with 10Ω and 47uF components at the op-amp supply leads.

- Relay supply issues could be related to unsoldered relay pins or issues with the protection diodes across the supply pins.

- LED supply at R14 would indicate issues with IC1, R14, or push switch soldering.

Mic-Pre Signal Testing

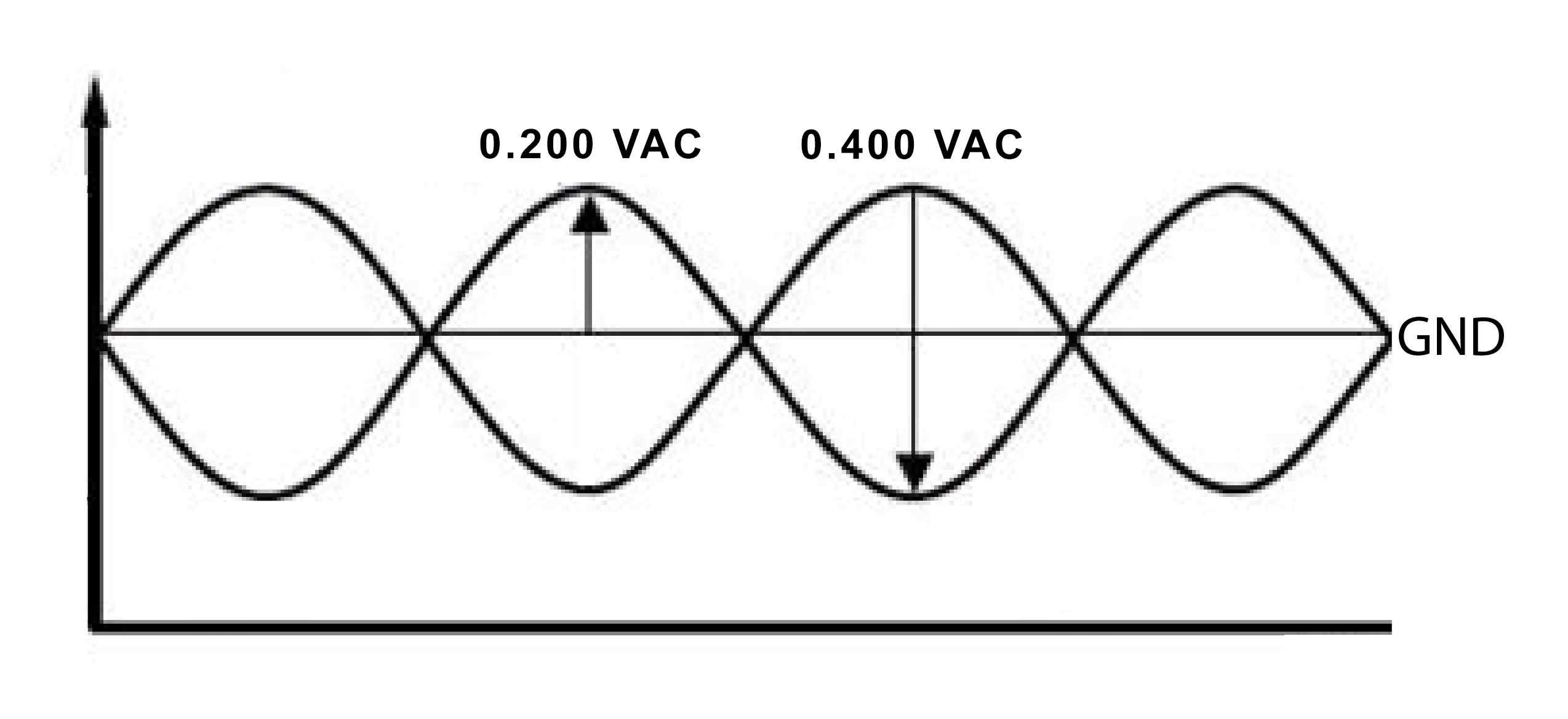

To isolate the issue, we’ll trace the signal through your Lola and figure out where the signal stops. The Lola is a fully differential mic-pre meaning both the “hot” signal and its 180° flipped “cold” signal are amplified in parallel through the unit. Rather than using ground as a reference for signal, we’re simply going to measure the AC voltage by placing one DMM probe on the hot signal and one probe on the cold signal. If at any point the voltage seems lower than expected, you can individually measure the hot and cold signal by referencing the GND pin. Keep in mind the voltage will be ½ the expected voltage. Polarity of the probes does not matter.

We’ll start by setting the controls as follows:

We’ll start by setting the controls as follows:

Gain: 3rd position (marked 26)

Output: Fully CW

Push Switches: All OFF

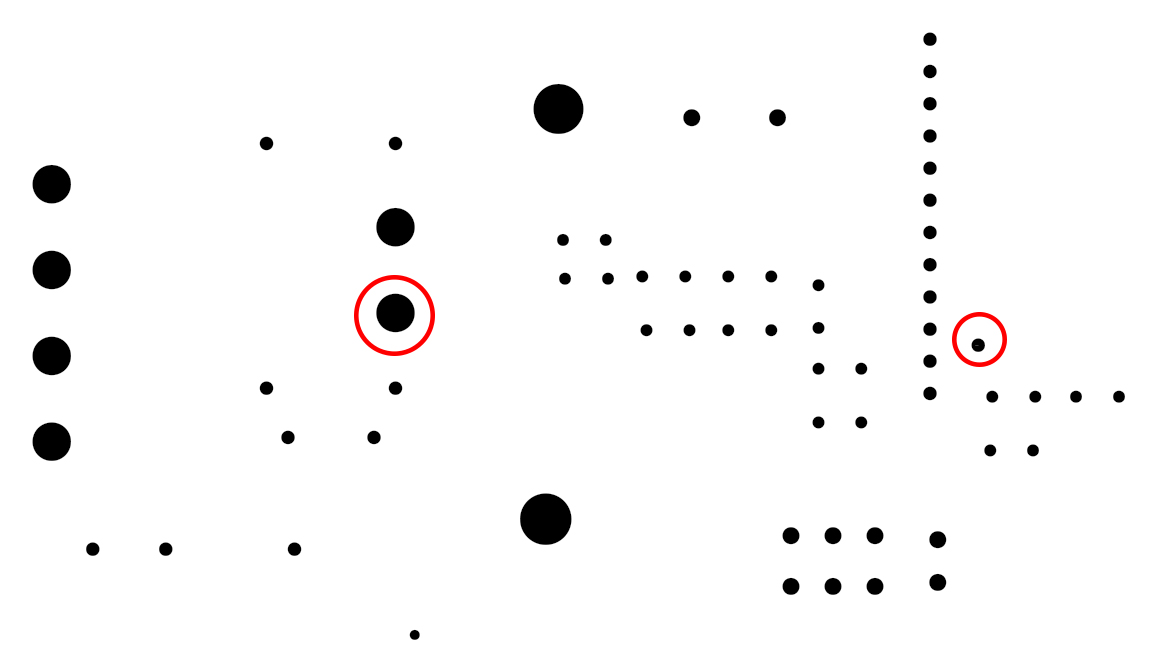

Using your analog signal generator or DAW input a 1KHz sine signal into your Lola. Adjust your signal generator output so your DMM reads 0.200 VAC (-11.5 dBu) across the edge card input pins labeled in the diagram below. Once your input level is established, work your way through the unit. Measure AC voltage between the two points labeled for each test point.

Signal Trace Test Point PDF Download

|

Test Points |

Description |

Expected Value |

|

1 |

Edge card inputs |

0.200 VAC |

|

2 |

Line relay poles |

0.200 VAC |

|

3 |

Line relay NC pads |

0.200 VAC |

|

4 |

Input tx primary |

0.200 VAC |

|

5 |

Input tx secondary |

0.400 VAC |

|

6 |

Op-amp non-inverting inputs |

0.400 VAC |

|

7 |

Op-amp outputs |

3.00 VAC |

|

8 |

Polarity relay poles |

3.00 VAC |

|

9 |

Output tx primary |

3.00 VAC |

|

10 |

Output tx secondary |

4.00 VAC |

|

11 |

Edge card outputs |

4.00 VAC |

You can see the gain staging of the mic-pre clearly. The input tx is wired as a 1:2 step-up and we can see the voltage gain double (+6dB) at the secondary. The op-amp gain is set by the gain switch. In the 3rd position the gain through the op-amp is +16dB. The output transformer is wired as a small step-up with +4dB of gain. Adding the in/out transformer fixed gain and the op-amp variable gain gives you the +26dB for this 3rd position.

Possible issues with bad voltages at test points:

- Unable to establish voltage at TP1 would indicate a signal shorting to ground. Try de-soldering input tx wires black and brown and see if you can establish a signal. If you can, you may have a bad input tx and should contact us.

- TP2 indicates a damaged trace or miss-measurement since TP2 is directly connected to TP1.

- TP3/TP4 indicates an issue with K1/K2 soldering, power supply, or damage.

- TP5 indicates a possible input tx issue or signal ground short at op-amp. Try removing the op-amps and see if your signal appears.

- TP6 indicates an issue with K1/K2 soldering, power supply, or damage. Also, possible signal ground short at op-amp. Try removing the op-amps and see if your signal appears.

- TP7/TP8 indicates an op-amp issue, gain switch and gain resistor issue, or signal ground issue at output tx.

- TP9 possible issue with K3 soldering, power supply, or damage.

- TP10 possible output tx issue or TPad.

- TP11 indicates a TPad issue or short at output.

Testing the Gain Switch Network

These resistors are in series so they can be tested with the unit unpowered and out of your rack. Set your Lola switch to the max gain setting. Start by setting your DMM to measure DC resistance and measure between the DOA2 “In –“ socket and the Grayhill switch pole lead. The pole is the lead on the Grayhill that is offset from the line of 12 leads.

The resistors add up in a ladder as you move from max gain to min gain. Working your way through the ladder will isolate a problem resistor, solder joint, or trace.

|

Gain Position |

Position Value |

DMM Reading |

|

12 (max gain) |

R1/6.2R |

6.2Ω |

|

11 |

R2/3.9R |

10 Ω |

|

10 |

R3/6.2R |

16 Ω |

|

9 |

R4/10R |

26 Ω |

|

8 |

R5/16.9R |

43 Ω |

|

7 |

R6/27R |

70 Ω |

|

6 |

R7/51R |

120 Ω |

|

5 |

R8/100R |

220 Ω |

|

4 |

R9/160R |

380 Ω |

|

3 |

R10/300R |

680 Ω |

|

2 |

R11/620R |

1.3 KΩ |

|

1 (min gain) |

R12/1.2K |

2.5 KΩ |

* The higher resistor values may take a few seconds to climb up on your DMM as the resistor ladder gets longer.

Meter Circuit

The output level meter is a typical VU style meter set to show +4dBu as 0 on the scale. It does not indicate clipping, it simply provides an output level reference.

Start by setting you unit to have an output of +4 dBu. This can be done with any input signal level, just confirm you have 1.22 VAC measured across edge card pins 2 and 4. Here is one way to do it:

Signal: -20dBu (0.077 VAC measured across edge card pins 8 and 10)

Gain: 3rd position

Output: Set for +4 dBu output (1.22 VAC across edge card pins 2 and 4)

Using the number schematic and PCB guide measure the voltages in your output meter circuit. We’ll be working through in a linear path so it should be obvious where the problem area lies. Pay attention when measuring for AC or DC and well as DC polarity. Your ground reference is labeled in the PDF below at pin 3 of the TL072.

|

Test Point |

Description |

Expected Value |

|

1 |

V+ supply |

+15 VDC |

|

2 |

V- supply |

-15 VDC |

|

3 |

Circuit input + |

0.350 VAC |

|

4 |

Circuit input - |

0.350 VAC |

|

5 |

Buffer/summing output |

1.22 VAC |

|

6 |

IC 103A output |

1 VAC |

|

7 |

IC 103B output |

+1.1 VDC |

|

8 |

Ref out |

+1.5 VDC |

|

9 |

Ref adj |

+0.26 VDC |

|

10 |

LED + supply |

+5.11 VDC |

|

11 |

LED - lead |

+2.8 VDC (LED off) |

Common errors include:

- TL071/TL072 swapped or inserted backwards

- LM3916 driver installed backwards

- LEDs installed backwards or not fully soldered

- Damaged diodes

- R106-R109 installed incorrectly (if you have no signal at IC102 output)

- Damaged ICs